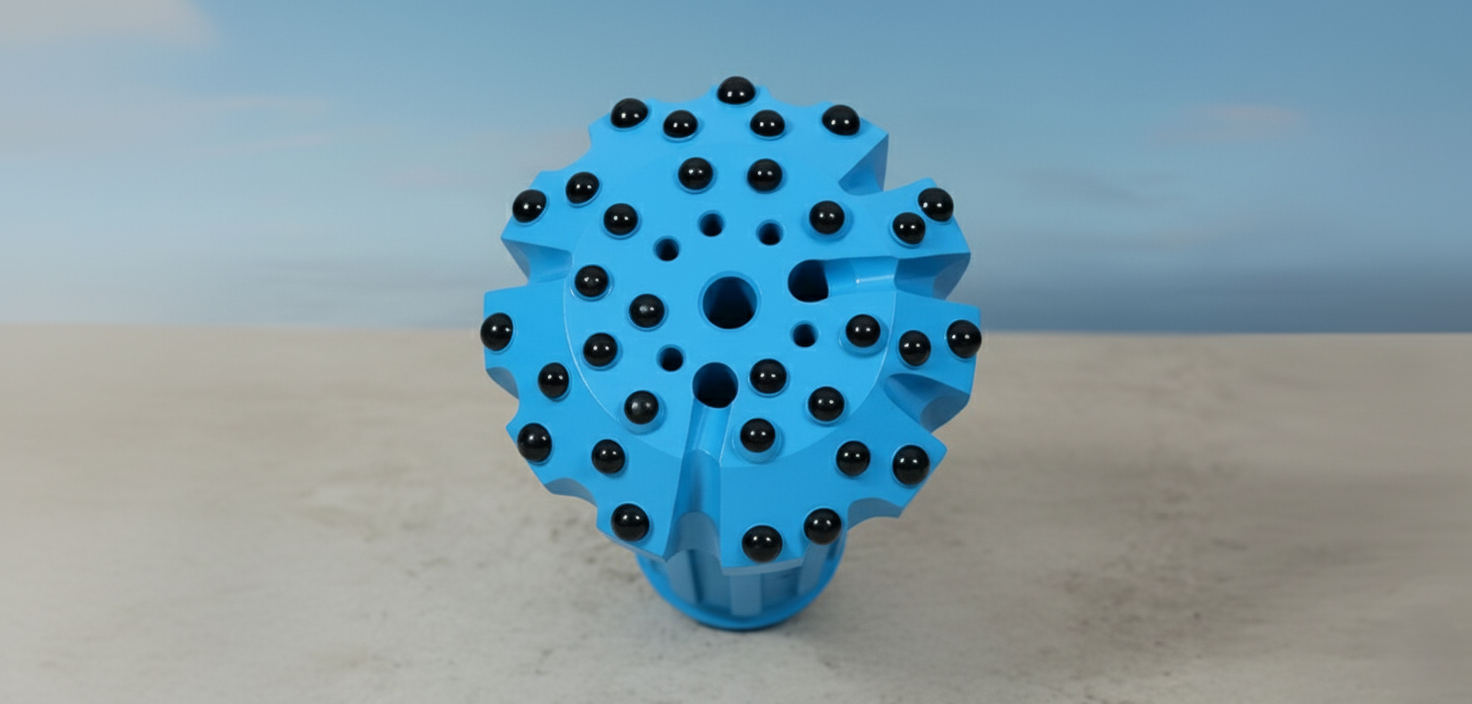

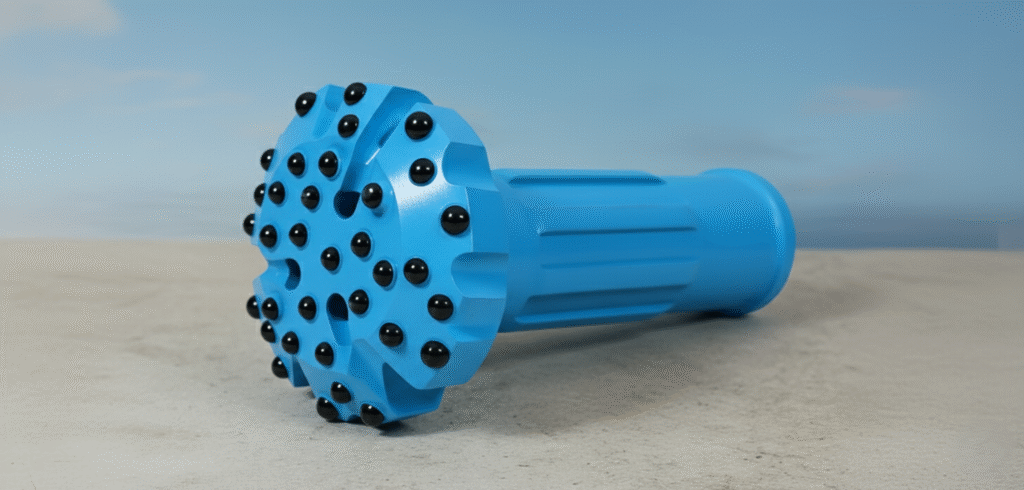

A DTH button bit is the cutting tool at the very end of a DTH drill string. It is attached to the shank of the DTH hammer and is responsible for making direct contact with the rock. The bit’s face is embedded with durable tungsten carbide “buttons” that crush and fracture the rock upon impact from the hammer’s piston. The design of the bit, including the shape and arrangement of the buttons, is engineered to optimize penetration, bit life, and hole straightness for different rock types.

DTH Button Bits:

4″-24″

Application:

Water Well & Mining

Suitable Formation / Strata:

Medium & hard

The Cutting Tool

Tungsten Carbide Buttons

Wide Diameter Range

Optimized Design

Efficient Rock Crushing

Application

Detailed Description:

The DTH button bit is the workhorse of the DTH drilling system. Its construction is key to its performance. The bit body is made from high-grade steel, and the face features an array of tungsten carbide buttons. These buttons are not just for show; they are the active cutting elements. As the hammer strikes the bit’s shank, the force is transferred to the buttons, which create micro-fractures in the rock. The drill string’s rotation ensures that the buttons strike a new area with each impact, leading to the formation of a circular hole. The design of the buttons—whether they are hemispherical, conical, or ballistic—influences the bit’s performance. For example, ballistic buttons are known for their high penetration rates in softer rock, while hemispherical buttons are more durable and suitable for harder, more abrasive rock. The flushing holes on the bit’s face also play a critical role, allowing the compressed air to efficiently clear the cuttings from the bottom of the hole and prevent the bit from becoming stuck.

What are the buttons on a DTH bit made of?

The buttons are made of tungsten carbide, a very hard and wear-resistant composite material that can withstand the intense impacts and abrasion encountered during rock drilling.

How long does a DTH button bit last?

The lifespan of a DTH button bit depends on several factors, including the type of rock being drilled (abrasiveness), the drilling parameters (hammer pressure, rotation speed), and proper maintenance. In some cases, bits can be resharpened to extend their life.

What is the purpose of the different button shapes?

Different button shapes are designed for different drilling conditions. For example, some shapes offer higher penetration rates, while others prioritize durability and a longer lifespan in highly abrasive rock formations.